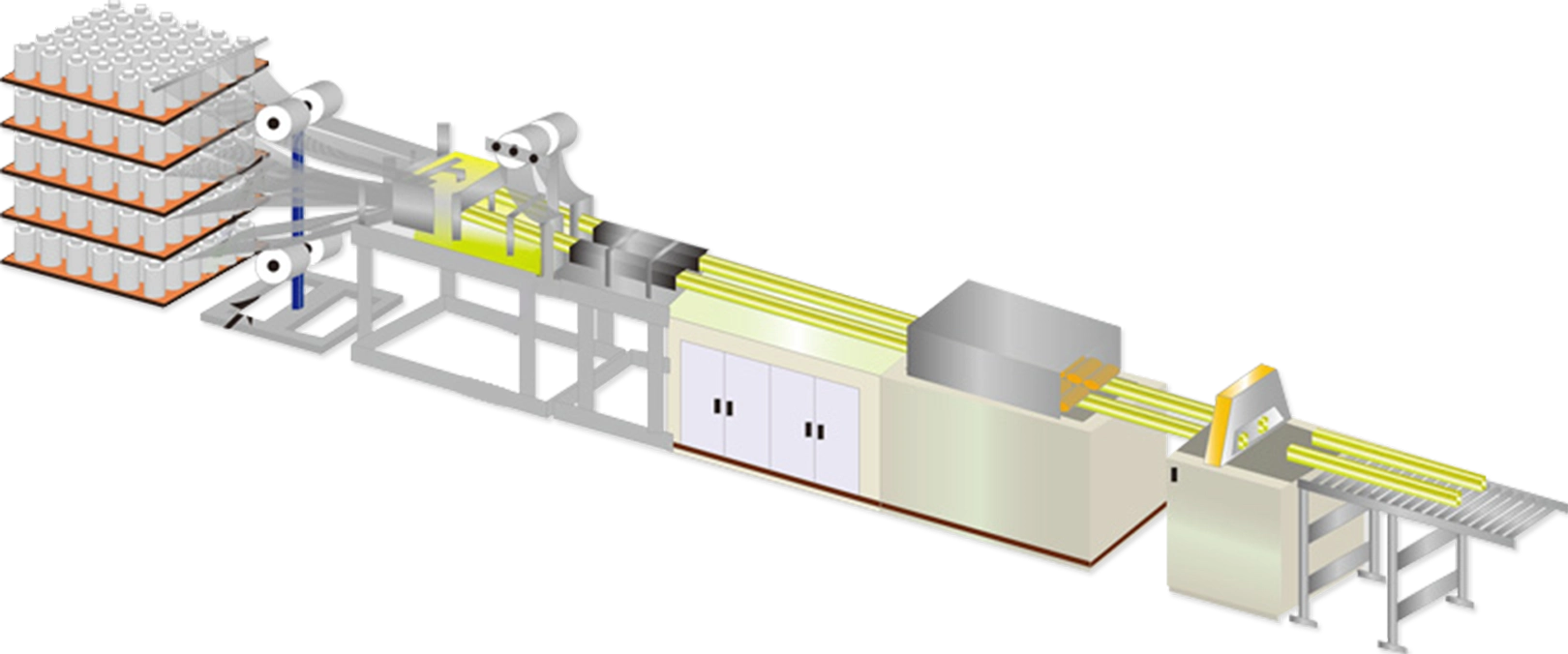

Reinforcing fibers are pulled from the creels. Fiber (roving) creels may be followed by rolled mat or fabric creels.

Fibers enter the resin bath where they are wetted and impregnated with liquid resin.

The wet fibers exit the bath and enter preformer where the excessive resin is squeezed out from fibers and the material is shaped.

The preformed fiber pass through a heated die where the resin cures, forming a solid composite profile.

The final cross-section dimensions are determined and the resin curing occurs.

The cured product is cut on the desired length.

Continuous process, suitable for mass production.

Possible to produce complex section profiles.

Customized production of complex cross-sectional profiles.

Fiber types can be a variety of options to increase the reinforcement.

Low production costs.

Great corrosion resistance and electrical properties.

#Sludge scraper #Scaffolding #Radome

#Fences #Frame #Building Reinforcement

#Trolling Motor #Cable Trays #Packing support frame

#Backpack #Horsewhip #Surfboard

#Marimba #Umbrella #Model

#Cable puller #Ladder #Hardware

FIBER LIN CO.,LTD. have a solid technical background, we can efficiently produce large orders with a continuous process and support the use of a variety of fiber materials to enhance product performance, whether it is a simple standard profile or a complex structure, which can be customized and accurately realized. If you have innovative R&D needs or unique product ideas, please contact us!

FIBER LIN CO.,LTD. dedicated to the production of glass and carbon fiber product. Since 2003, it has been recognized and trusted by customers for its stable quality and production capabilities. Our products are widely used in industry, construction, sports and other fields, and we will continue to innovate and grow in the future, seek more technical cooperation, explore more advanced technologies and processes, and provide higher quality solutions!